Technical Advantage

Huachong company has established a R&D team led by academician YouweiDu, and has carried out long-term R&D cooperation with well-known universities and institutes in China such as Nanjing University and Chinese Academy of Sciences, the cooperation includes the SmCo permanent magnetic materials’ researches as follows: the trial production of new products, the innovation of production technology, the improvement of operation performance, etc. At present, we have achieved excellent R&D results in high performance, high temperature resistance and high stability, and has already mass produced a series of high-quality SmCo magnets for our customers.

The unique nano-cellular structure is an important factor for the excellent magnetic properties of SmCo magnets. Huachong has made the significant progress in the production efficiency, performance, consistency and other key parameters through the continuous improvement of the chemical composition, heat treatment process and powder manufacture process. Mastering the correlation between the microstructure and magnetic properties of SmCo permanent magnet materials, Huachong is able to provide customers with in-depth customized products and technical services.

Huachong company could supply a series of high-quality SmCo magnets as follows: 1) HCM-35H grade, which the magnetic performance currently is the highest for available SmCo product in the world; 2) HCM-T550 grade, which has high temperature resistance and the operation temperature currently is the highest for available SmCo product internationally; 3) SmCo permanent magnets with low intrinsic coercivity (10-13 kOe), which are developed according to customers’special requirement; 4) HCM-T18D grade, which the temperature coefficient is lower than general SmCo magnet, and the magnetic performance currently is the most stable for available SmCo magnets internationally; 5) High-performance insulated SmCo permanent magnet components with wide working temperature range of -200 ℃ to 200 ℃ Internationally.

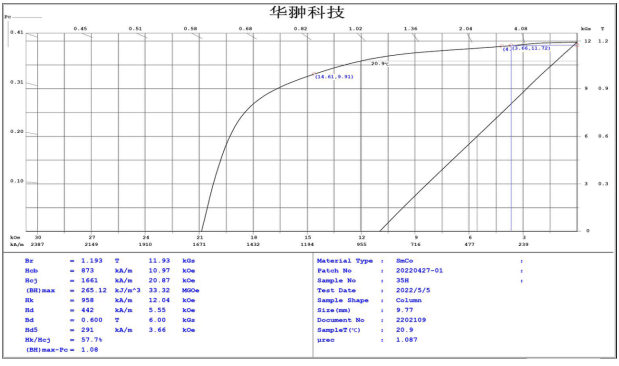

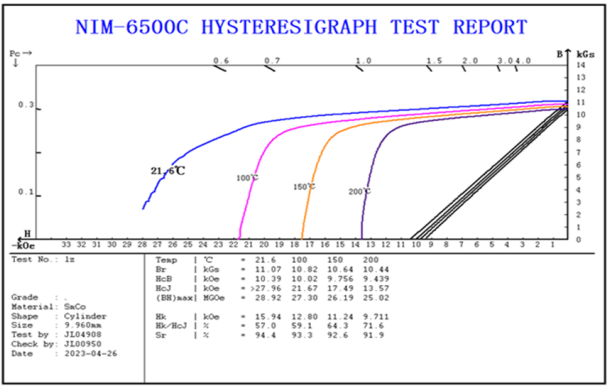

1. HCM-35H (Material: Sm2Co17)

The magnetic parameters at room temperature as follows: (BH)max: 33~35 MGOe; Br: 11.8~12.0 kGs; Hcj: ≥20 kOe.

The temperature coefficient of Br (20°C~200 °C): -0.038%/°C;

The temperature coefficient of Hcj (20°C~200 °C): -0.27 %/°C.

At 200°C, (BH)max: 27~29 MGOe

Maximum operating temperature: 250 °C.

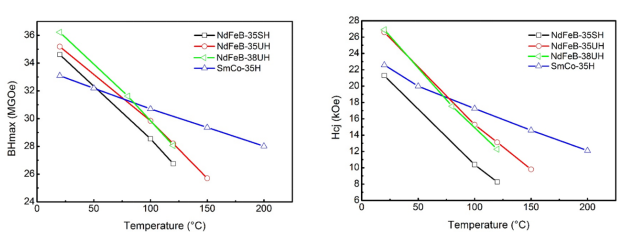

HCM-35H grade material currently has the highest magnetic property among all the SmCo products internationally at 20-200 °C, and has been well applied in the field of permanent magnet motors. Compared with sintered neodymium-iron-boron 35SH, 35UH, and 38UH materials, HCM-35H grade material has slightly lower magnetic performance at room temperature, but it obviously has better temperature stability. At around 80 °C, its magnetic energy product exceeds that of neodymium-iron-boron 35UH material, and at around 100 °C, its magnetic energy product exceeds that of neodymium-iron-boron 38UH material, therefore, it has the potential to replace high-coercivity neodymium-iron-boron materials at relatively high temperature.

Target application fields: high-end motors, high-power microwave devices, etc.

1.1 B-H curve

1.2 Comparison among HCM-35H, Neo 35SH, Neo 35UH, and Neo 38UH as follows:

2. HCM-T550 (Material: Sm2Co17)

The magnetic parameters at room temperature as follows: (BH)max: 20~24 MGOe; Br: 9.4~9.8 kGs; Hcj: ≥20 kOe.

The temperature coefficient of Br (20°C~550 °C): -0.053%/°C.

The temperature coefficient of Hcj ( 20°C~550 °C): -0.15 %/°C.

At 550°C, (BH)max: 5~7 MGOe.

Maximum operating temperature: 550 °C.

HCM-T550 grade material currently has the highest magnetic properties among all available SmCo products internationally at a maximum operating temperature of 550 ° C. It has rather good thermal stability, and its effective operating temperature has been increased from 350 °C to 550 °C compared with 24H grade SmCo products which the magnetic properties are similar with HCM-T550 at the room temperature.

Target applications: military industry, aerospace industry and automobile, tec.

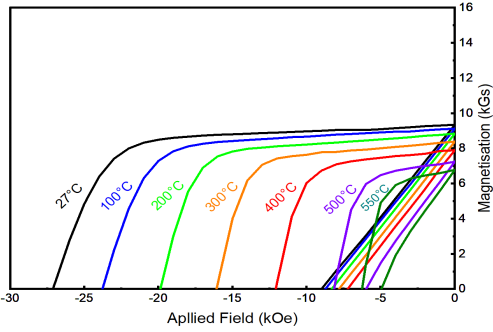

2.1 B-H curve

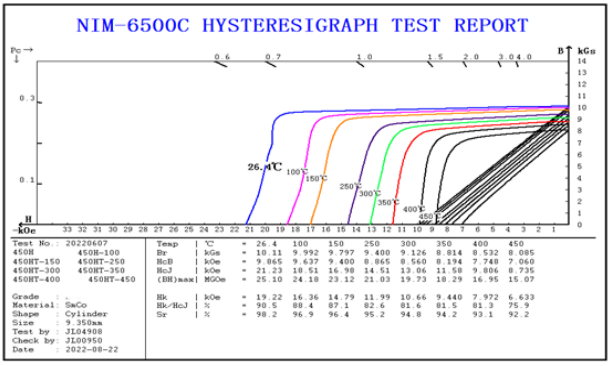

3. High temperature resistance HCM-T450 (Material: Sm2Co17)

The magnetic parameters at room temperature as follows: (BH)max: 23~26 MGOe; Br: 10.1~10.4 kGs; Hcj: ≥20 kOe.

The temperature coefficient of Br (20°C~450°C): -0.047%/°C.

The temperature coefficient of Hcj (20°C~450°C): -0.14 %/°C.

At 450°C, (BH)max: 15~16 MGOe.

Maximum operating temperature: 450 °C.

HCM-T450 grade material currently has the highest magnetic properties among all available SmCo products internationally at a maximum operating temperature of 450 ° C.

Target application fields: exploration and chemical fields which require extremely high magnetic stability.

3.1 B-H curve

4. Low coercivity series SmCo (Material: Sm2Co17)

Hcj is only 10-15 kOe for HCM-33M/30M/28M/26M/24M SmCo materials, Hcj is only 5-10 kOe for HCM-33L/30L/28L/26L/24L SmCo materials,.

The SmCo materials of M series and L series are used in relays or other fields which have special requirements on material’s coercivity. The products are easily magnetized and have been supplied to some public companies.

Target application: the devices which are magnetized after assembly.

4.1 B-H curve of HCM-28M grade

5. HCM-TC30 (Material: Sm2Co17)

The magnetic parameters at room temperature as follows: (BH)max: 27~30 MGOe; Br: 10.6~11.0 kGs; Hcj: ≥20 kOe.

The temperature coefficient of Br (20°C~450°C): -0.026~-0.032%/°C.

HCM-TC30 grade material can provide not only the same magnetic properties as normal 30H grade SmCo material but also higher magnetic temperature stability.

The temperature coefficient of Br for normal 30H grade SmCo material is -3.5%%/° C~-4.0%/° C at 20 °C ~200 °C, in comparison, the temperature coefficient of HCM-TC30 grade material has been reduced by more than 15%.

Target application fields: high-power rail transit traction motors, etc.

5.1 B-H curve

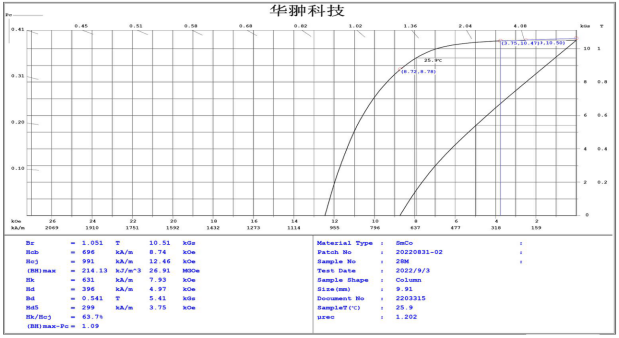

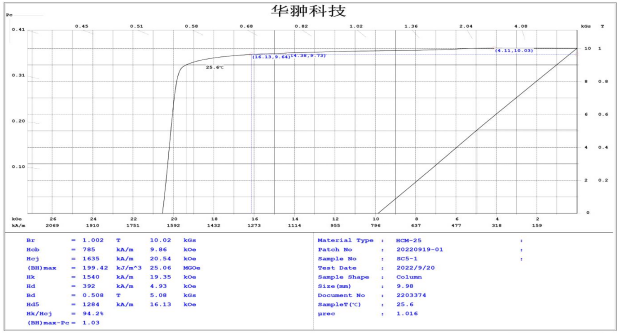

6. HCM-25 (Material: SmCo5)

The magnetic parameters at room temperature as follows: (BH)max: 24~26 MGOe; Br: 9.9~10.1 kGs: Hcj: ≥20 kOe.

Maximum operating temperature: 250 °C.

HCM-25 grade material can provide the highest magnetic energy product among all 1:5 type samarium-cobalt materials internationally.

Target application fields: high-end electromechanical devices, precision instruments, etc.

6.1 B-H curve

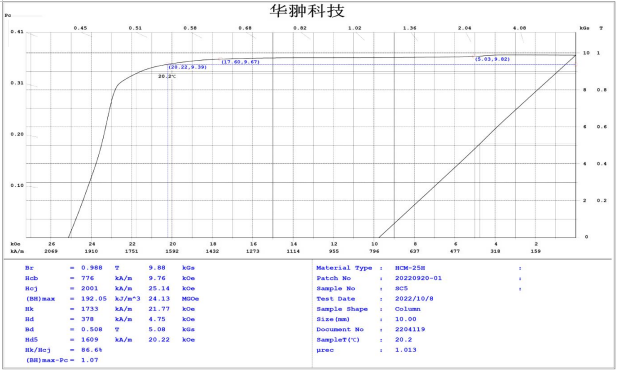

7. HCM-25H (Material: SmCo5)

The magnetic parameters at room temperature as follows: (BH)max: 23~25 MGOe; Br: 9.8~10.0 kGs; Hcj: ≥25 kOe.

Maximum operating temperature: 250 °C.

Compared with HCM-25 grade material, HCM-25H grade material can provide similar magnetic energy product but higher Intrinsic coercivity among all 1:5 type samarium-cobalt materials.

Target application fields: high-end electromechanical devices, precision instruments, etc.

7.1 B-H curve

8. High resistivity series SmCo

Combined with insulative phases, the laminated samarium-cobalt material has been successfully developed. The laminated samarium-cobalt material not only has the resistivity of more than 800 μΩ•cm but also keep the previous high magnetic performance, its resistivity has been increased by more than 10 times compared with normal magnets.

High resistivity series SmCo has high resistance and high magnetic performance, and can maintain insulation at -200 °C to 200 °C.

Target application fields: high-end electromechanical devices and other industries.

8.1 Photos: