Rear earth permanent magnetic materials (REPMMs) are based on intermetallic compounds made of rare earth metal elements RE (Sm, Nd, Pr, etc.) and transition metal elements TM (Fe, Co, etc.).

Benefited from the characteristic orbital and spin magnetic moment of 3d and 4f electrons, REPMMs typically exhibit excellent intrinsic magnetic properties, such as high Curie temperature, high saturated magnetization intensity, strong magneto-crystalline anisotropy, etc. REPMMs are currently a type of permanent magnetic materials with the highest coercive force & the largest magnetic energy product. Since the 1960s, with three breakthroughs of magnetic energy product, three generations of REPMMs with wide applications have been successfully developed: first-generation SmCo5 material, second-generation Sm2Co17 material, third-generation Nd2Fe14B material.

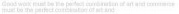

As the first and second generations of REPMMs, the samarium-cobalt permanent materials have excellent magnetic properties (high remanence, high coercivity, high magnetic energy product), very low temperature coefficient, very high operation temperature (up to 550°C) and strong corrosion resistance, which is the permanent magnetic material with the best temperature resistance currently. Therefore, samarium-cobalt permanent magnetic materials are widely used in microwave devices, electron beam devices, high-power/high-speed motors, sensors, magnetic components, etc.

Characteristics Comparison of Different Permanent Magnetic Materials

Material Type | Magnetic Energy Product | Demagnetization Resistance | Temp. Coefficient of Br | Temp. Coefficient of Hcj | Operation Temperature |

Nd2Fe14B | highest | strong | high | highest | Lowest |

Sm2Co17 | high | strongest | low | Low | high |

SmCo5 | medium | strong | medium | medium | low |

AlNiCo | low | weak | lowest | lowest | highest |

Ferrite | low | medium | highest | ﹨ | low |

Remark: Temp. coefficient of Hcj for ferrite is positive.

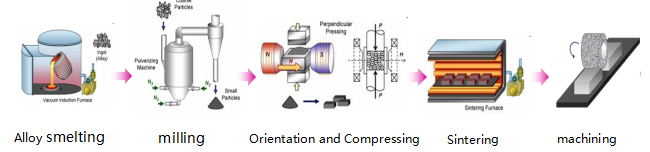

Process Flow

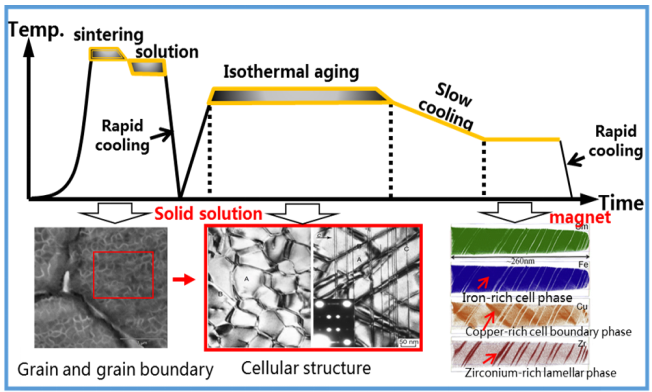

Sintering process